Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

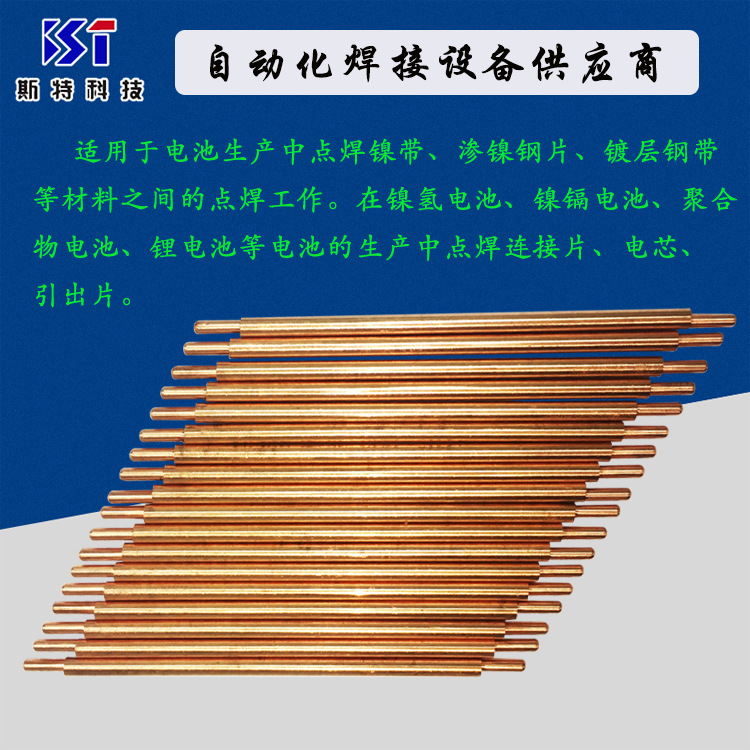

Battery Spot Welding Needle Electrode

Warm Tip: 5 pairs of welding needles = 10 starts, 20 pairs = 40 or more postage 1. products Application scope: spot welding between nickel strip, nickel infiltrated steel sheet, coated steel strip and other materials in battery production. In the production of nickel-hydrogen batteries, nickel-cadmium batteries, polymer batteries, lithium batteries and other batteries, spot welding connecting pieces, batteries, lead-out pieces.

Classification:

welding electrode

Key words:

Battery Spot Welding Needle Electrode

immediate consultation

Product Description

Warm Tip: 5 Pairs of Welding Needles = 10 Beats, 20 Pairs = 40 or More Postage

1. Product Application Scope: Spot Welding between Nickel Strip, Nickel Permeated Steel Sheet, Coated Steel Strip and Other Materials in

Battery Production. In the production of nickel-hydrogen batteries, nickel-cadmium batteries, polymer batteries, lithium batteries and other batteries, spot welding connecting pieces, batteries, lead-out pieces.

2. product features:

1. Avoid sticking electrode phenomenon.

2. The welding part is not yellow and the welding spot is beautiful.

3. Avoid false welding.

4. Reduce the generation of welding sparks.

5. Excellent electrical conductivity and thermal conductivity.

6. Good high temperature performance.

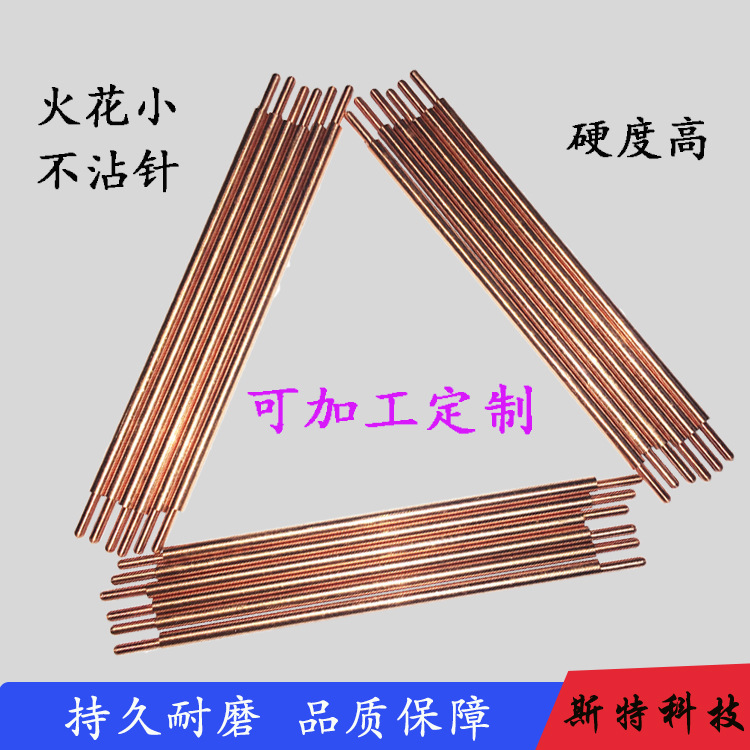

Tips: After the

welding needle is exposed to the air for a period of time, the bottom will become rough and burr, which will affect the welding effect and aesthetics. A small file can be used to smooth the bottom to remove the accumulation of oxidation, enhance the beauty of the welding surface and reduce the occurrence of needle sticking.

Shenzhen Sester Technology Co., Ltd. is a technology research and development company specializing in the development and production of lithium battery assembly equipment such as single-sided battery pack automatic spot welding machine, energy storage spot welding machine, inverter

DC spot welding machine, AC spot welding machine, precision spot welding machine, ultrasonic metal welding machine, battery sorting machine, and

non-standard automatic welding equipment and related consumables. The company has 16 years of industry experience, has a complete and scientific quality management system, is Shenzhen strength and professional coexistence of resistance welding solution. The integrity, strength and product quality of Shenzhen Sester Technology Co., Ltd. have been recognized by the industry. Welcome friends from all walks of life to visit, guidance and business negotiation.

resistance welding material expert ---- aluminum oxide copper (nano-alumina dispersion strengthened copper)

aluminum oxide copper ---- specially designed for galvanized steel plate, nickel plate, nickel strip, Aluminum alloy, stainless steel, brass and other spot welding design.

Features:

The softening temperature is as high as 930 ℃, which is relatively high in copper alloy, but lower than tungsten copper (1000 ℃). The conductivity of

is as high as 85% IACS, and the heat dissipation performance is between tungsten copper (220 W/M.K) and pure copper (390W/m-k).

Products:

resistance welding electrode head, electrode cap, electric welding wheel, electrode arm, etc.

Conductive nozzle, vacuum switch, electrical connector, contact, etc. for cutting and gas shielded welding.

service fields of electrical engineering, electronics and communications, automobiles, home appliances and container manufacturing, molds, etc.

The properties of dispersion strengthened copper are derived from the addition of alumina. The size of alumina particles is 3~12 nm, and the particle spacing is about 50~100 nm. Its thermal stability is excellent, and it can still maintain the original particle size and particle spacing even at a temperature close to the melting point of copper. The addition amount of dispersive phase only accounts for a small volume fraction of the matrix and hardly affects the inherent physical and chemical properties of the matrix metal. Therefore, its softening temperature is as high as 930 ℃, at the same time, the electrical and thermal conductivity, as well as the hardness and strength can be maintained very well.

spot welded galvanized sheet not bonded-aluminum oxide copper electrode

spot welded stainless steel not bonded-aluminum oxide copper electrode

spot welded nickel strip not bonded-aluminum oxide copper electrode

spot welded brass not bonded-aluminum oxide copper electrode

spot welded aluminum alloy not bonded-aluminum oxide copper electrode

Previous Page

Previous Page

Next Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!