Language: Chinese

Service Hotline

About Us

automatic welding equipment

power battery PACK line equipment high-tech production enterprises

Shenzhen Sester Technology Co., Ltd. is a high-tech production enterprise integrating R & D, production and sales of automatic welding equipment and power battery PACK line equipment. The company has the ability to independently develop new products, strong technical development force, and has a professional technical engineering team to provide customers with timely and perfect pre-sales and after-sales service. product core technology has 16 years of professional experience in the industry...

Professional core technical experience in the industry

Long-term cooperative enterprise

Product core category

Factory Floor Area

Top Recommendations

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

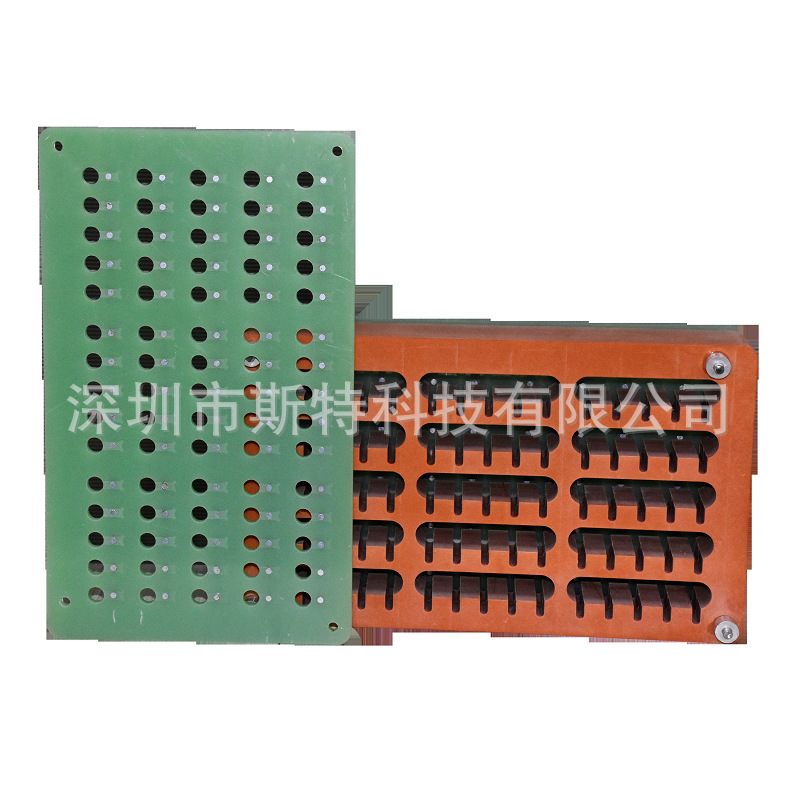

Battery automatic spot welding machine

Automatic spot welding machine for special-shaped battery pack

Battery automatic spot welding machine

Automatic spot welding machine for single-sided battery pack

Battery automatic spot welding machine

Mobile power charging treasure battery pack automatic spot welding machine

Battery automatic spot welding machine

2A battery semi-automatic spot welding machine

Battery automatic spot welding machine

Double-sided battery pack automatic spot welding machine

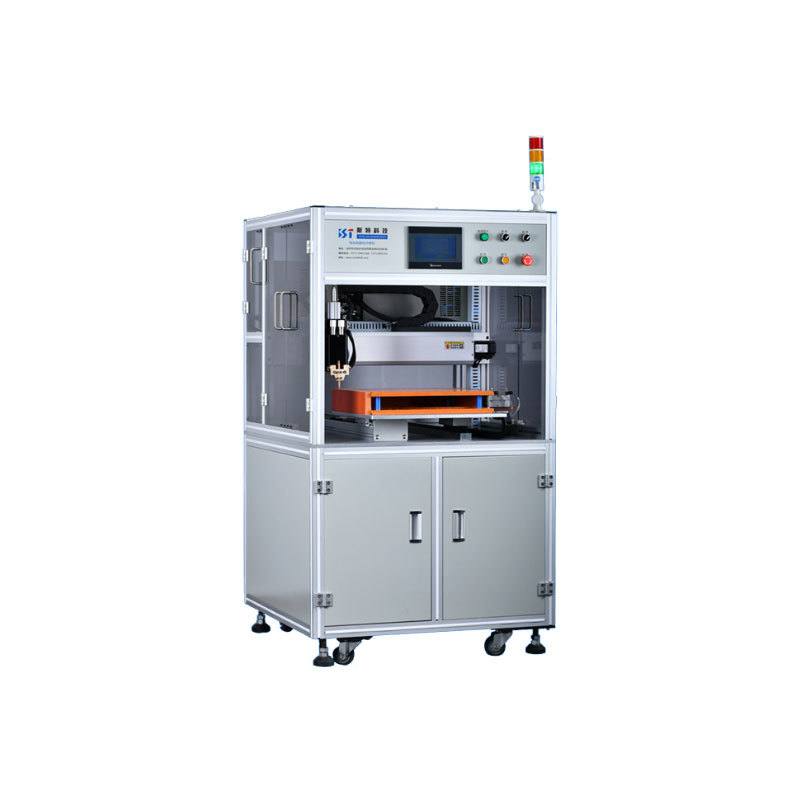

Gantry type battery spot welding machine

ST-2011A gantry type precision energy storage spot welding machine

Gantry type battery spot welding machine

MDC-6000 gantry transistor spot welder

Gantry type battery spot welding machine

IST-8000 Gantry Inverter DC Spot Welding Machine

Gantry type battery spot welding machine

IST-5000 Gantry Inverter DC Spot Welding Machine

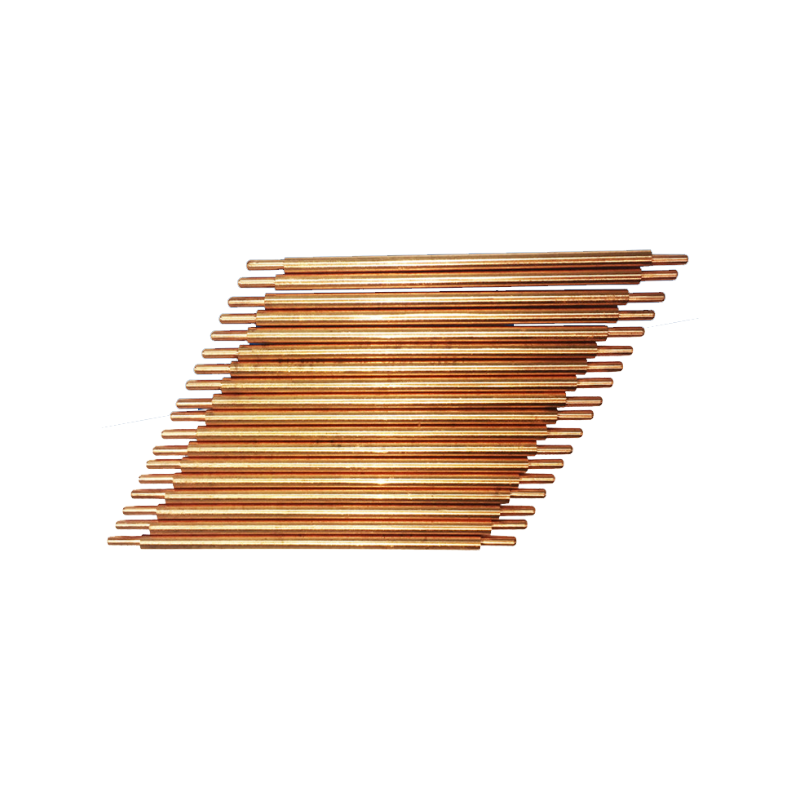

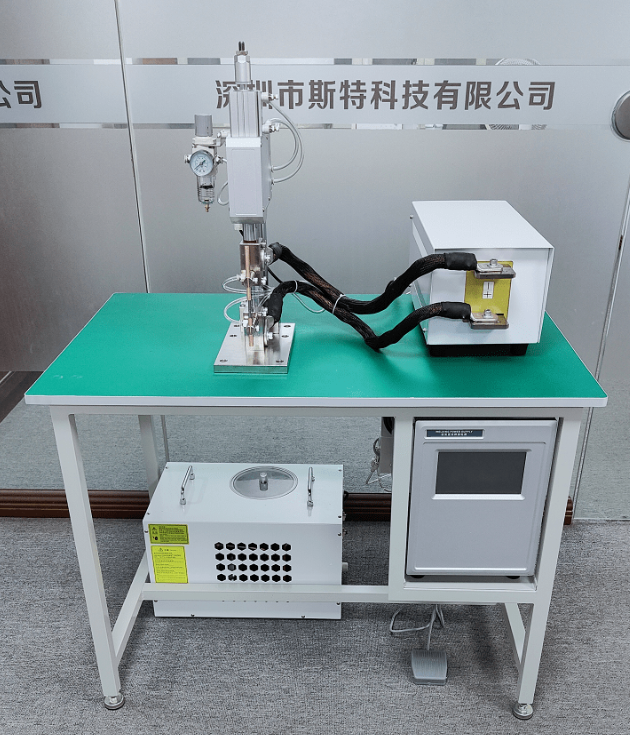

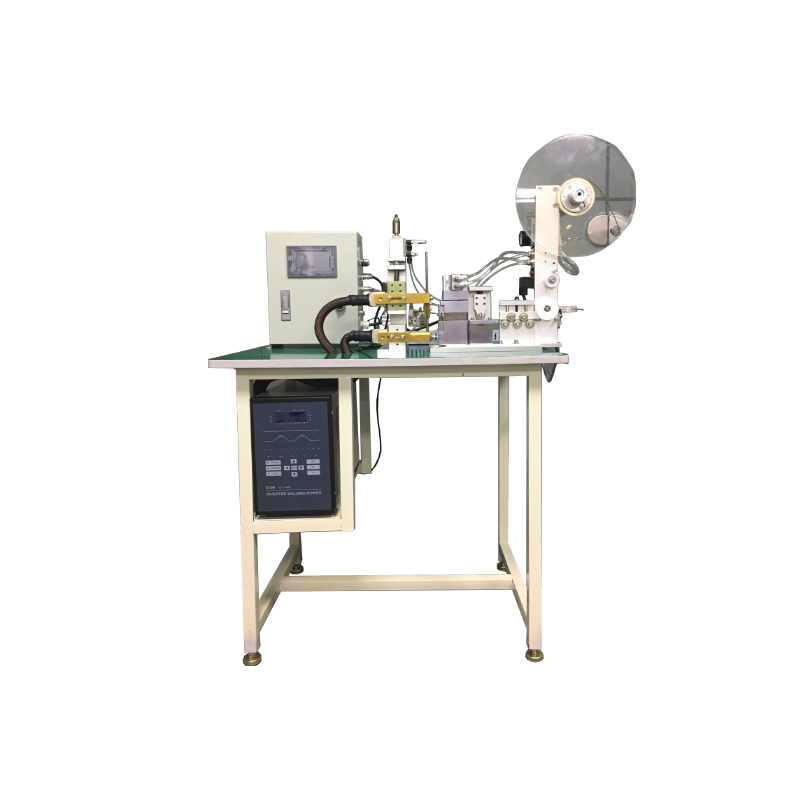

automatic feeding wire bonding machine

ST-D800 automatic feeding wire bonding machine

automatic feeding wire bonding machine

ST-D500 automatic nickel sheet wire bonding machine

automatic feeding wire bonding machine

automatic feeding wire bonding machine

automatic feeding wire bonding machine

automatic feeding wire bonding machine

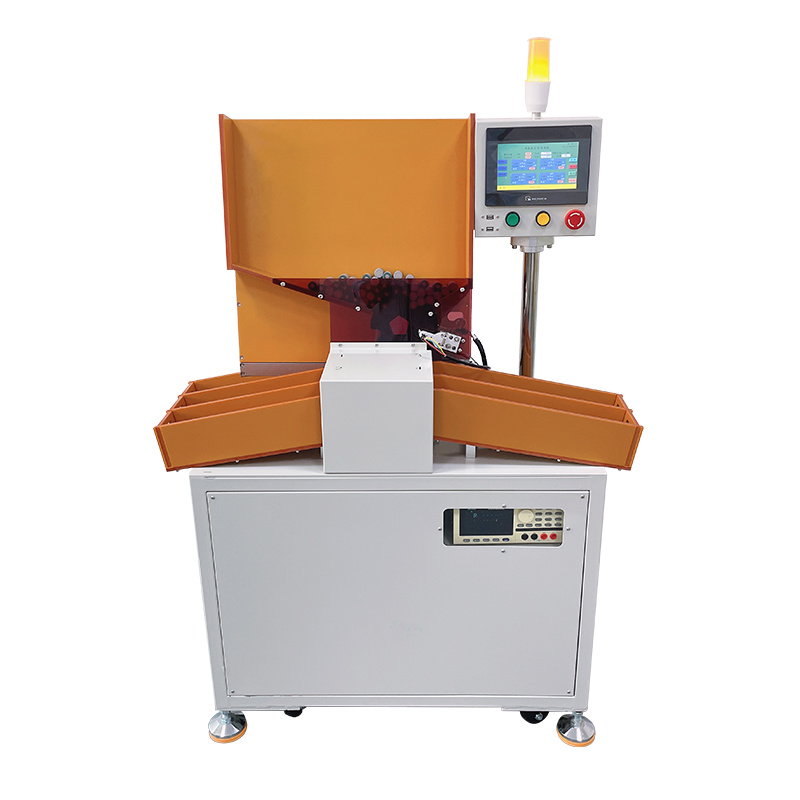

Automatic battery sorting machine

ST-FX10 ten-speed battery cell automatic sorting machine

Automatic battery sorting machine

ST-FX05 five-speed battery cell automatic sorting machine

Products->Automatic battery sorting machine

Ten-channel battery separator

Automatic battery sorting machine

Battery five-speed sorting machine

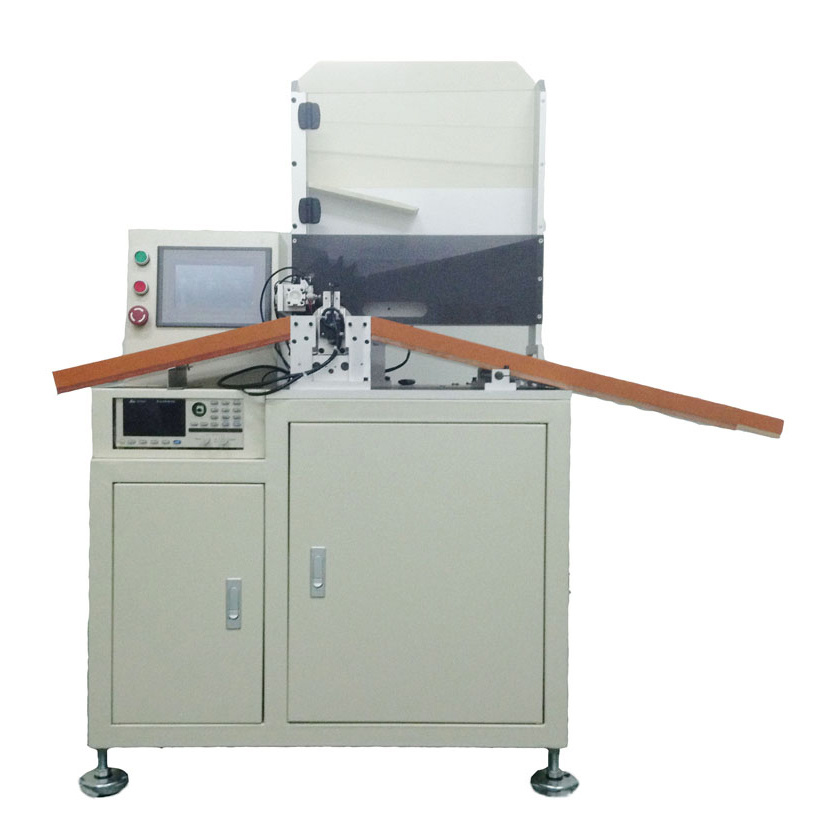

Automatic barley paper pasting machine

ST-TZ18 automatic barley paper pasting machine

Automatic barley paper pasting machine

Battery automatic barley paper pasting machine

Full quality service

Have a professional technical engineering team to provide customers with timely and perfect service, so that you have no worries

Pre-sales service

One-to-one introduction of product features and profiles for users to choose high-quality, low-cost products and provide solutions

Button

Service in Sale

Strictly arrange product quality inspection, delivery and other stages of work, so that all work before product shipment is carried out in an orderly manner.

Button

After-sales service

During the installation and commissioning of the equipment, senior engineers will be sent to the site to guide the installation and commissioning free of charge to ensure the normal operation of the product.

Button

Application areas

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Automobile Manufacturing

automobile making

Metal processing

metalworking

3C electronic

3C Electronics

Advertising Logo

Advertising signage

Partners

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

News

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production