Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

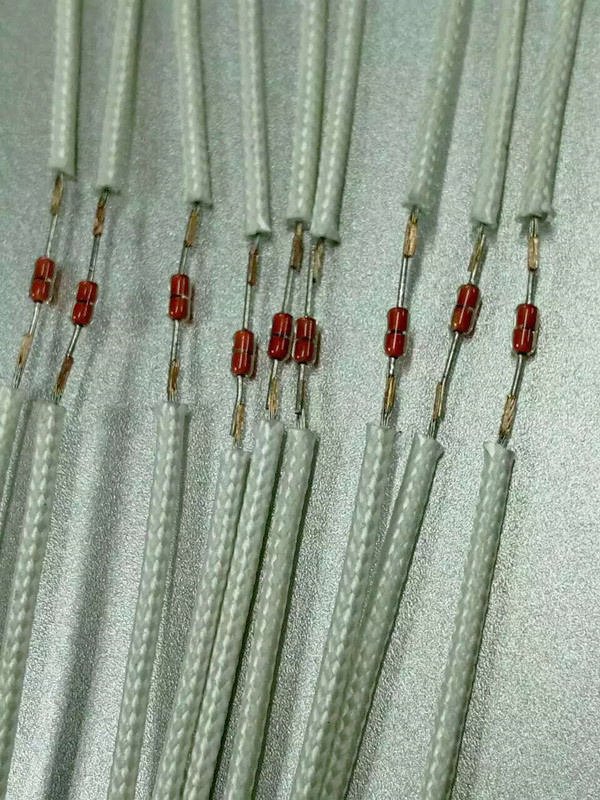

Sensor thermistor spot welding machine

Model of inverter DC spot welding machine: IST-2000 IST-3000 IST-5000 medium frequency inverter DC resistance welding control power supply is composed of single-phase or three-phase AC power through a rectifier circuit to pulsating DC power, which is converted into an intermediate frequency square wave through an inverter circuit composed of power switching devices and connected to a transformer. After step-down, it is rectified into DC power with less pulsation to supply electrodes for welding the workpiece. Inverters usually use current feedback pulse width modulation to obtain stable constant current output. The intermediate frequency inverter spot welding machine has superior performance and is suitable for welding thin metal parts with high thermal conductivity and fine workpieces.

Classification:

electronic hardware resistance welding

Key words:

Sensor thermistor spot welding machine

immediate consultation

Product Description

Equipment Overview

Intermediate Frequency Inverter DC Resistance Welding Control Power Supply is composed of single-phase or three-phase alternating current into pulsating direct current through a rectifier circuit, which is converted into an intermediate frequency square wave connected to a transformer through an inverter circuit composed of power switching devices, and then rectified into direct current with less pulsation after step-down to supply electrodes for welding workpieces. Inverters usually use current feedback pulse width modulation to obtain stable constant current output. The intermediate frequency inverter spot welding machine has superior performance and is suitable for welding thin metal parts with high thermal conductivity and fine workpieces.

IST inverter DC spot welding machine features

1. Induction load voltage, feedback control constant current, to achieve high-quality welding.

2. The power-on mode of PRE HEAT and MAIN HEAT is preheated before welding to ensure stable welding quality.

3. Maintain the continuity of energy density, short welding time, and reduce the deformation and discoloration of the base material. (Welding time is controlled in microsecond units, continuous output mode).

4. Easy to change from low current to high current, suitable for precision welding.

5. The upper and lower limits of the current can be set to simply judge whether the welding quality is good or not, which is suitable for welding automation instruments.

6. The welding current rises with the power-on time to ensure the welding result.

power parameters:

Model |

IST-1500 |

Input Power (V) |

Single Phase AC 220 V ± 10% 50/60Hz |

Output Current (a) |

0~1500 |

inverter frequency (HZ ) |

4000 |

rated power (KVA ) |

12 |

No-load voltage (V) |

8 .0 |

control mode |

constant current control |

cooling mode |

forced air cooling |

Welding Conditions |

8 |

Usage |

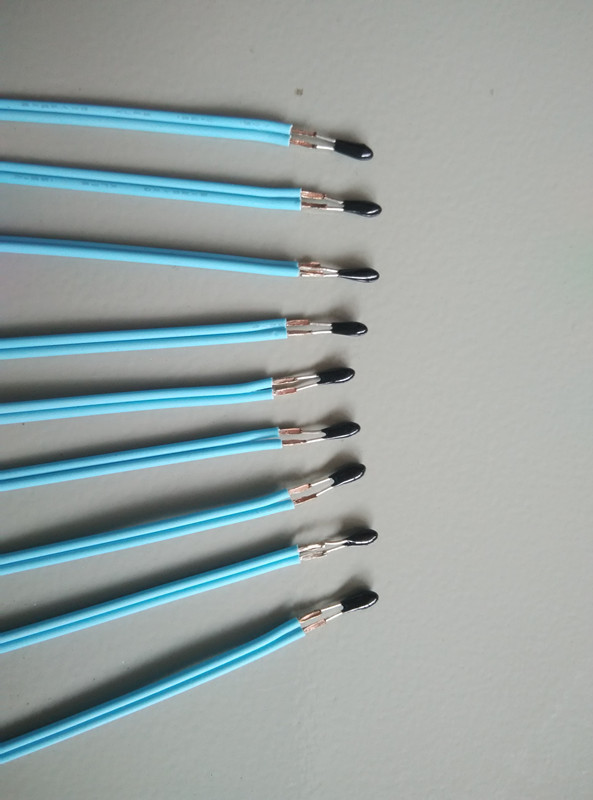

Electronic Parts, Tantalum Capacitors, Nickel Plating, Temperature Sensors, etc. |

Weight (Kg) |

16.5 |

Exterior Dimension (W×H×D) |

185 × 280 × 420 |

Application Case

Previous Page

Previous Page

Next Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!