Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

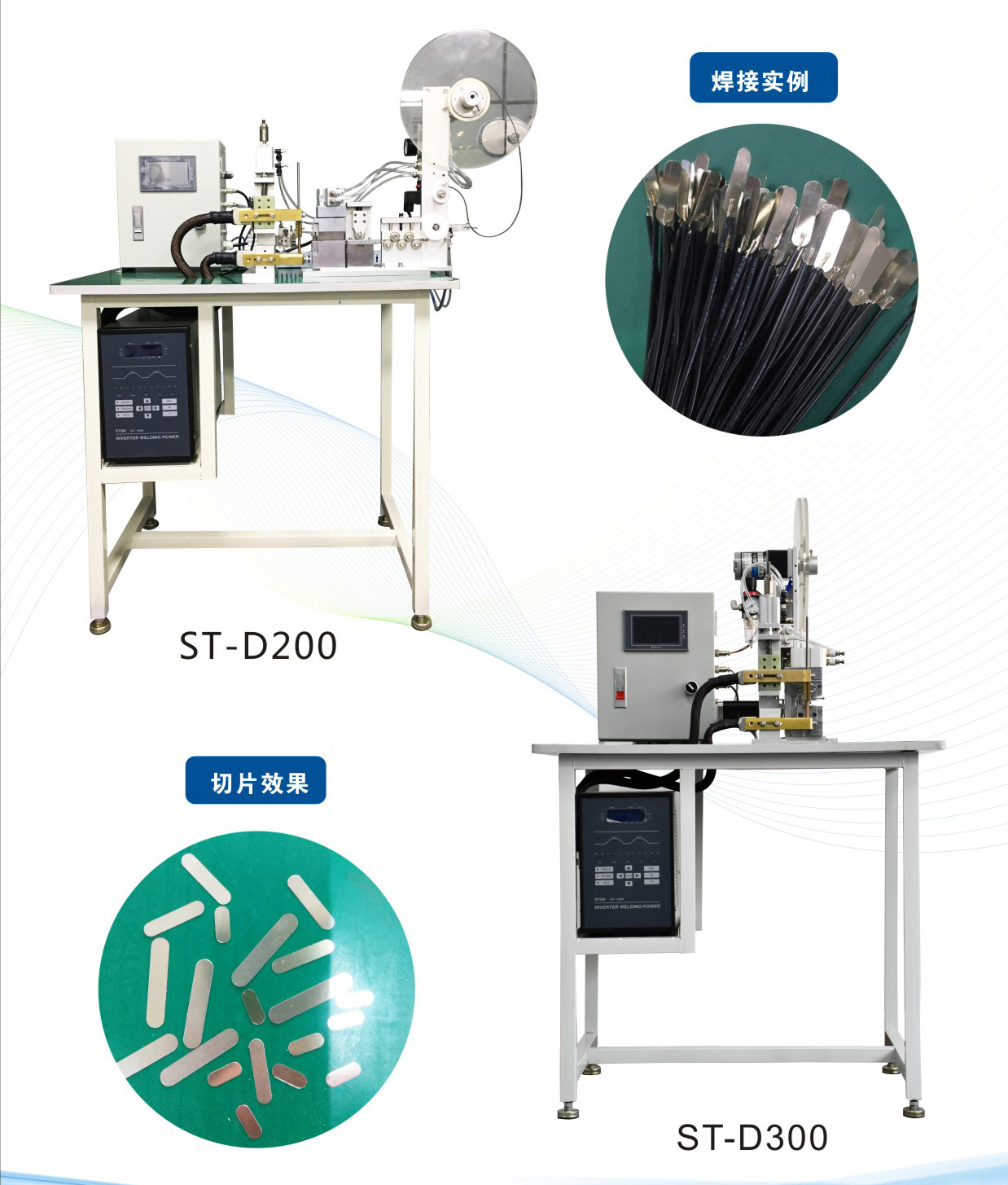

automatic cutting nickel sheet wire bonding machine

Classification:

automatic feeding wire bonding machine

Key words:

automatic cutting nickel sheet wire bonding machine

immediate consultation

Product Description

Previous Page

Previous Page

Next Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!