Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

20k ultrasonic metal spot welding machine

Application Principle of Ultrasonic Metal Welding Machine The application of ultrasonic metal welding machine has 20kHz -40kHz. Its principle is to use the energy of ultrasonic high-frequency mechanical vibration to weld the same or different non-ferrous metal materials. During the welding process, neither current nor high-temperature energy is transmitted to the workpiece, but the surface of the workpiece is vibrated cyclically at a high frequency of 20kHz -40kHz, and the corresponding pressure is applied to the workpiece to form a solid-state combination between the workpieces to achieve the welding effect. Ultrasonic metal welding used in lithium batteries is to weld conductive materials with different poles. The welding requirements are relatively high. The use of ultrasonic technology for welding is a better welding equipment for battery manufacturers. The main materials are (nickel sheet and copper sheet, aluminum Strip and aluminum foil, aluminum-nickel composite tape and aluminum shell, etc.).

Classification:

ultrasonic metal spot welding machine

Key words:

20k ultrasonic metal spot welding machine

immediate consultation

Product Description

1. Ultrasonic Metal Welding Machine Application Principle

Ultrasonic Metal Welding Machine Application has 20kHz -40kHz. Its principle is to use the energy of ultrasonic high-frequency mechanical vibration to weld the same or different non-ferrous metal materials. During the welding process, neither current nor high-temperature energy is transmitted to the workpiece, but the surface of the workpiece is subjected to cyclic vibration at a high frequency of 20kHz -40kHz, and the corresponding pressure is applied to the workpiece to form a solid-state combination between the workpieces to achieve the welding effect. Ultrasonic metal welding used in lithium batteries is to weld conductive materials with different poles. The welding requirements are relatively high. The use of ultrasonic technology for welding is a better welding equipment for battery manufacturers. The main materials are (nickel sheet and copper sheet, aluminum Strip and aluminum foil, aluminum-nickel composite tape and aluminum shell, etc.).

Advantages of 2. Ultrasonic Metal Welding Machine

1) The welding material does not melt and does not have fragile metal characteristics.

2) After welding, the conductivity is good, and the resistivity is extremely low or nearly zero.

3), low requirements for welding metal surface, oxidation or electroplating can be welded.

4), welding time is short, without any flux, gas, solder.

5), welding without sparks, environmental protection and safety

3. ultrasonic metal welding machine performance and technical parameters

1. Metal welding machine specifications, technical parameters:

| Operating frequency | 25KHZ |

| Rated power | 1000W-2000W |

| Input voltage | AC220V,50/60HZ |

| working air pressure | 0.2-0.8MPA |

| working mode | pneumatic, relay program control |

2. performance characteristics: (high welding efficiency, good welding quality and good after-sales service)

(1) adopts American ultrasonic technology, semi-automatic frequency tracking;

(2) adopts time relay to complete time and welding procedure;

(3) The main accessories adopt original imported accessories, with high energy conversion and utilization efficiency;

(4) The circuit is equipped with frequency offset and excessive current protection devices to ensure the stability of the equipment;

(5) Select low-cost replaceable welding nozzle, the welding nozzle is extremely hard, which greatly reduces the wear of the welding nozzle. The integrated high-hardness welding head has multiple welding surfaces that can be installed quickly, thus reducing the cost.

(6) The welding die can be quickly and conveniently replaced and installed according to different application sizes, effectively reducing the cost:

(7) The installation, debugging and operation of the equipment are simplified.

4. Ultrasonic Metal Welding Machine Application Range

1), Ni-MH Battery Ni-MH Battery Ni-MH Battery Ni-Mesh and Ni-Sheet Mutual Melting and Ni-Sheet Mutual Melting.

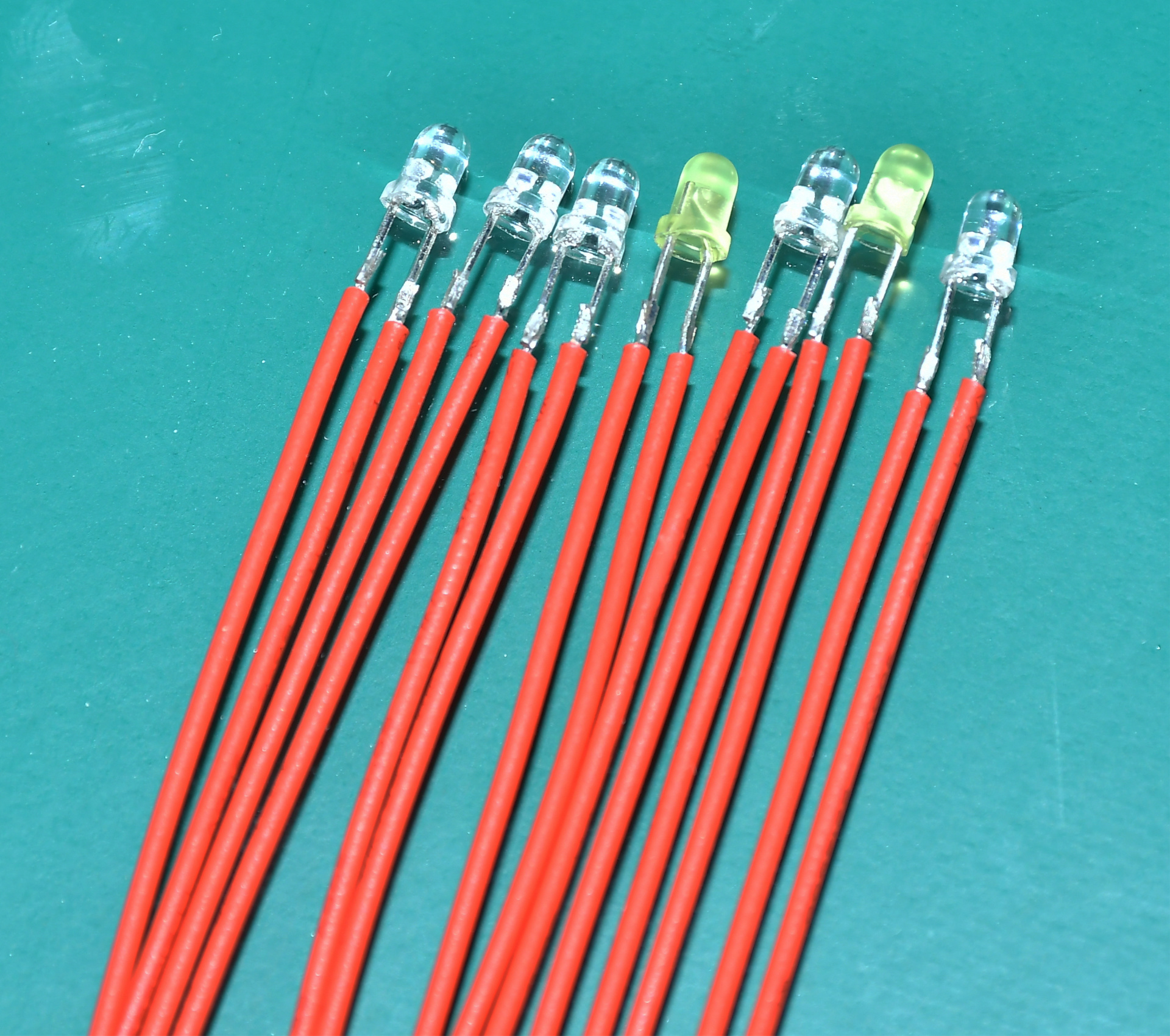

2), lithium battery, polymer battery copper foil and nickel sheet mutual fusion, aluminum foil and aluminum sheet mutual fusion.

3), wire mutual fusion, partial formation of one and multiple mutual fusion.

4), wires and famous electronic components, contacts and connectors are mutually fused.

5), famous household appliances, automotive supplies of large heat dissipation seat, heat exchange fins, honeycomb heart mutual fusion.

6), electromagnetic switches, fuse-free switches and other high-current contacts, mutual melting of dissimilar metal sheets.

7), metal pipe sealing tail, cut off can be water, airtight.

metal material welding suitability:

| Metal Material | Suitability |

| Brass | OK |

| Aluminum | OK |

| Copper | OK |

| Gold | OK |

| silver | OK |

| tin | OK |

| nickel | OK |

common fault list

| fault phenomenon | fault cause | solution |

| Power on No Instruction | Fuse Blown | 1: check whether the power tube is burned out, 2: replace fuse |

| according to the test, ammeter does not show | 1: power tube is burned out, 2: high voltage capacitor is burned out, 3: relay control part is faulty, 4: the line on the back of the main circuit board is burned out |

to replace related accessories |

| according to the test, the current is too large or there is a squeal. | 1: transducer, horn, welding head is not locked, 2: if there is no horn, the current is large, there is a problem with this transducer or horn, 3: the characteristics of the power tube are varied or burnt out, 4: the power amplification part is faulty. |

to replace related accessories |

| step on the foot switch, the welding head does not come down or the control time is not allowed | 1: there is a problem with the solenoid valve, 2: there is a problem with the time relay. |

replace solenoid valve or time relay |

Next Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!