Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

Metal ultrasonic welding equipment

Classification:

ultrasonic metal spot welding machine

Key words:

Metal ultrasonic welding equipment

immediate consultation

Product Description

1. project name: metal ultrasonic welding equipment

2. model: UM-20K (attached figure)

3. equipment working principle

ultrasonic metal welding machine has 20KHZ-40KHZ in application, its principle is to use the energy of ultrasonic high-frequency mechanical vibration to weld the same or different non-ferrous metal materials, and neither transmit current to the workpiece during the welding process, it does not transmit high temperature energy to the workpiece, but in the workpiece with 20KHZ-40KHZ high frequency in the surface of the cycle of vibration, and the corresponding pressure on the workpiece to form a solid state between the workpiece to achieve the welding effect.

4. equipment technical parameters

1, working frequency: 20KHZ (automatic frequency tracking)

2, rated power: 3000W/4000W

3, input voltage: AC220V,50/60HZ;

4, working air pressure: 0.2-0.8MPA

5, cylinder stroke: 20MM, cylinder diameter 63MM;

6, welding time: 0 - 9.999S

7, quick connector: 8MM air pipe in-line type;

8, transducer system: German imported chip

9, chassis peripheral size: 380LX130WX240H

head peripheral size: 460LX220WX360H

10, total weight of the whole machine: 40KG

5. equipment performance requirements

(1) adopt American ultrasonic automatic frequency tracking technology, avoid the inconvenience of manual frequency modulation, automatically detect frequency when starting up, have secondary ultrasonic vibration time, and are more convenient and simple to use.

(2) Built-in computer digitization of various parameters, automatic compensation amplitude, small amplitude when no load, synchronous amplification of amplitude and power when load is increased, thus, the transducer and welding head mold are effectively protected and the welding accuracy is higher.

(3) The power output adopts digital stepless linear adjustment, and the output power is freely selected from 50% to 100. The internal power amplification adopts full-bridge IGBT module, which has high ultrasonic conversion rate and maximum ultrasonic power can reach 4000W, which can meet various welding requirements.

(4) More advanced protection circuit, the output sound wave is overloaded, the mold is suddenly broken and overloaded, and the built-in computer detection circuit cuts off the output in a very short time, thus protecting the internal circuit;

(5) High-speed switching up to 135 times per minute can be adapted to various Non-standard automation equipment welding.

(6) welding head is integrated with 360 degrees of free rotation, which can quickly change welding surface and improve efficiency. The gap between welding head and bottom die is adjustable.

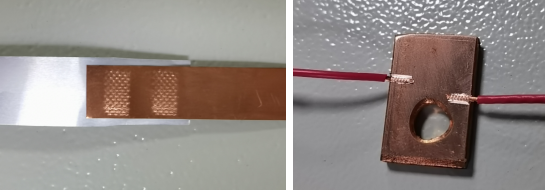

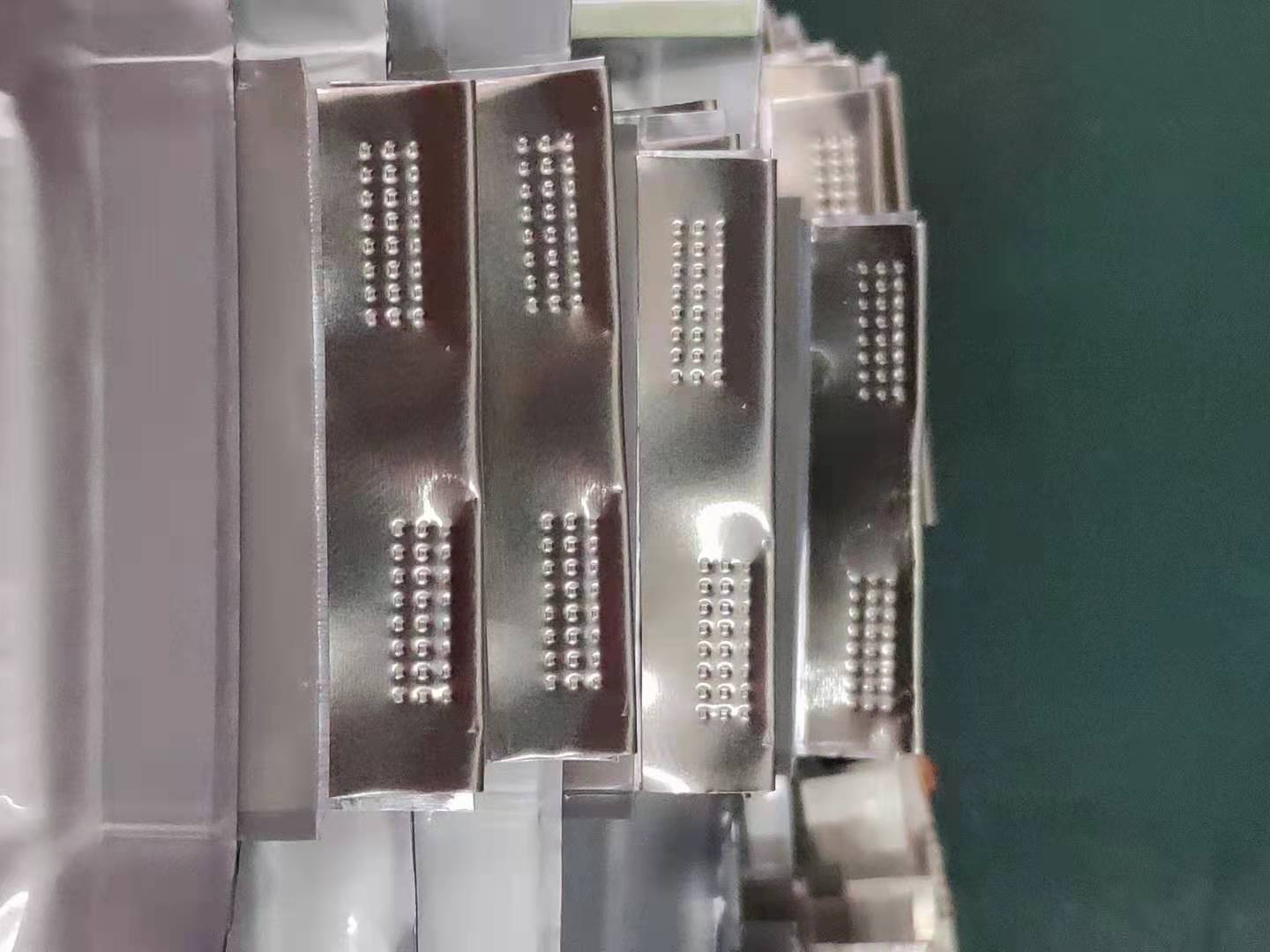

(7) Welding spot specification: single-point two-sided welding head, welding teeth can be customized according to sample requirements.

(8) Welding head material: high hardness material imported from Germany;

(9) Applicable welding materials: laminated welding within 100 layers, 0.2 nickel sheet +0.2 copper sheet welding, etc.;

(10) Welding effect: firm welding, low internal resistance, no virtual welding.

6. supply parts list

sequence |

says |

number quantity |

description description |

1 |

Power Box |

1 |

Operation Settings |

2 |

Welding Rack |

1 |

|

3 |

transducer + horn |

1 |

to convert energy, adjust amplitude |

4 |

welding head |

1 |

Germany imported steel |

5 |

bottom mold |

1 |

|

6 |

foot switch |

1 |

start operation |

7 |

machine adjustment tool |

1 |

Equipment Debugging and Maintenance |

8 |

Operation Manual |

1 |

Guidance Work Book |

9 |

Cable |

Several |

are used to connect |

pneumatic components: original Yadke Die Material: German Alloy Steel |

|||

7. Welding Legend

8. Applicable Requirements for Complete Machine

① The main components of the equipment are metal structures;

② Equipment is two main components, namely power box and rack;

③ The power supply of the equipment is a stand-alone power supply.

9. equipment after-sales technical service

9.1 is guaranteed for one year from the date of delivery, and will continue to provide paid technical services one year later.

9.2 guarantee that within 48 hours after receiving the user's request for maintenance services.

9.3 two welding surfaces of a welding head, and the number of welding is guaranteed to be used more than 200000 times.

9.4 transducer is guaranteed to be used for more than one year, and it will be replaced free of charge within one year.

10. Installation and Training

10.1 The seller shall install the equipment at the user's factory site;

10.2 Training: During the installation period, the seller shall provide training for the factory operators on site, including normal operation, maintenance, analysis of operation problems and emergency handling procedures. The installation training time is 1 working day.

11. Installation instructions

11.1 place the machine in a stable horizontal place, and the equipment should be placed in a place free of corrosive gas and dry operation.

11.2 do not place the machine in a dusty place.

11.3 Avoid placing them in places prone to direct sunlight, etc.

Previous Page

Previous Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!