Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

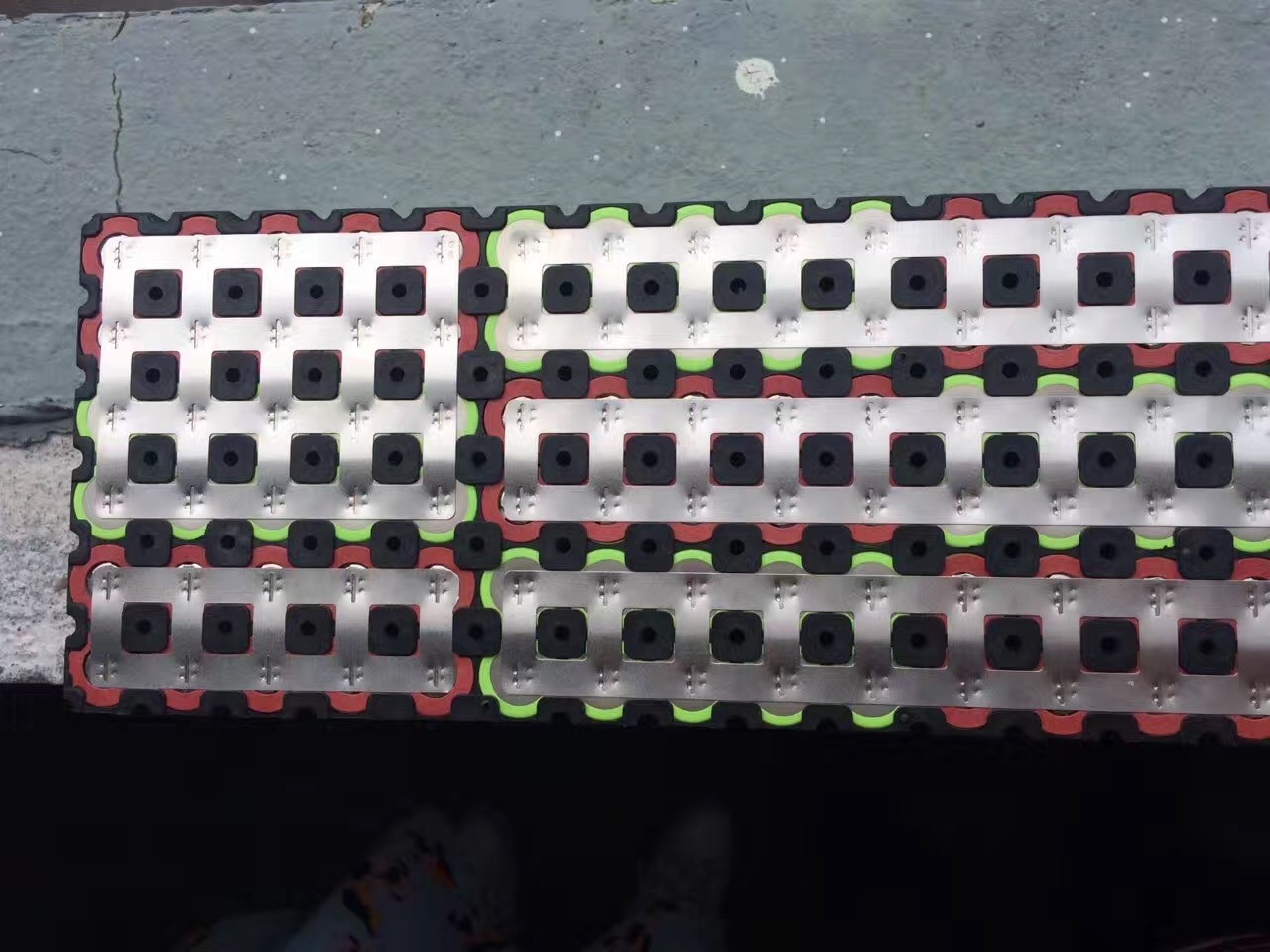

Double-sided battery pack automatic spot welding machine

Classification:

Battery automatic spot welding machine

Key words:

Double-sided battery pack automatic spot welding machine

immediate consultation

Product Description

Equipment Introduction

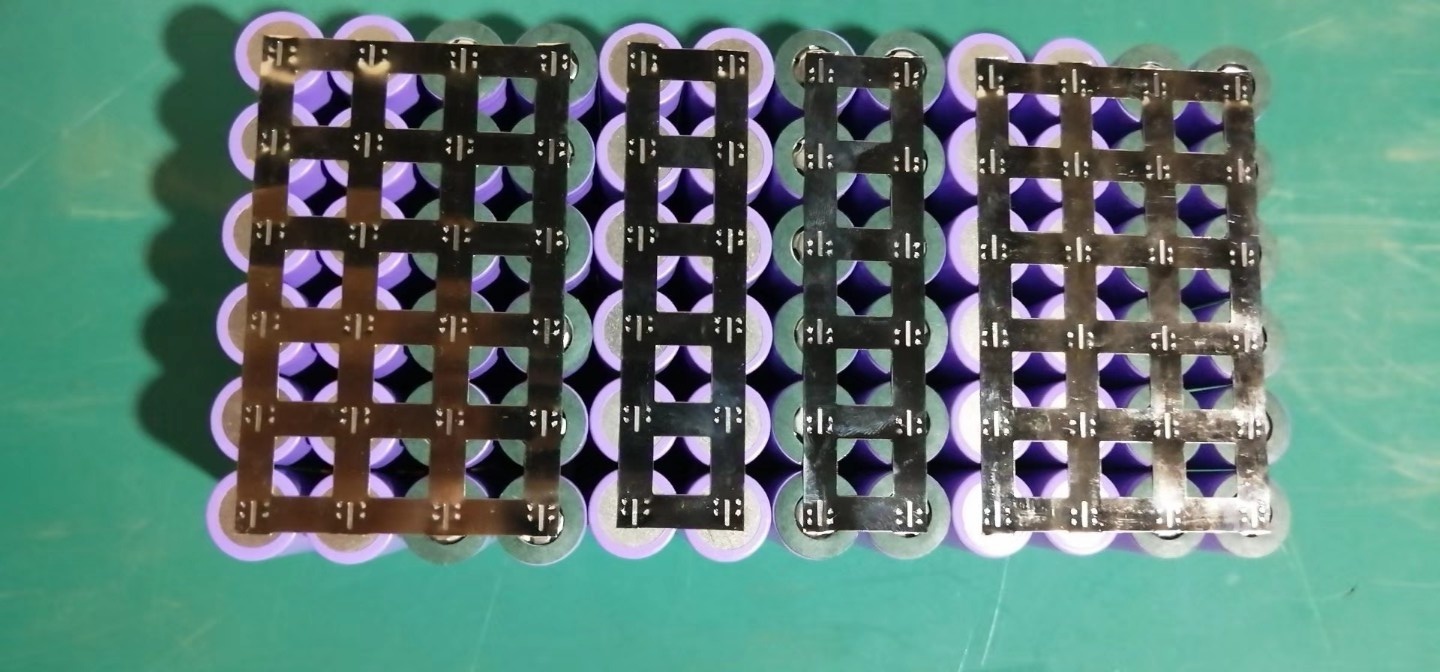

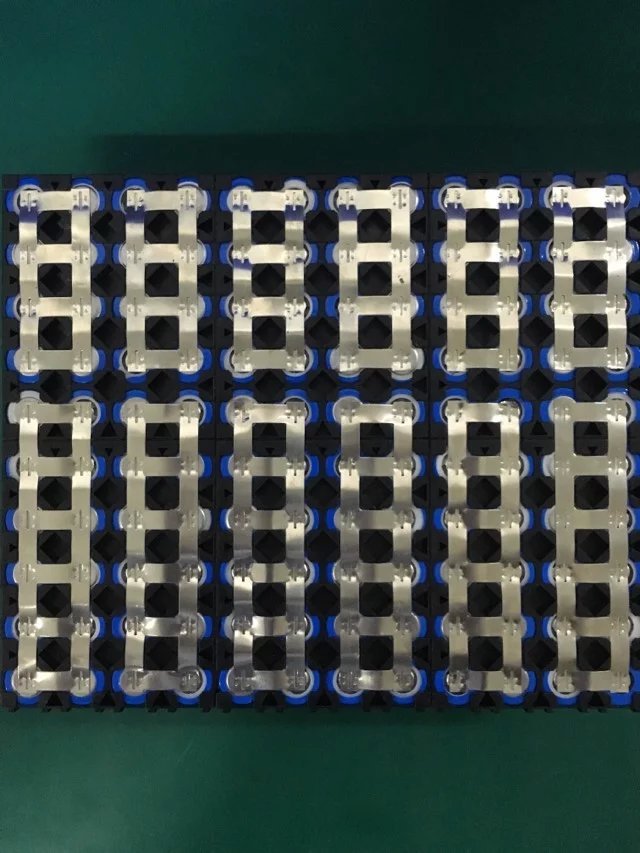

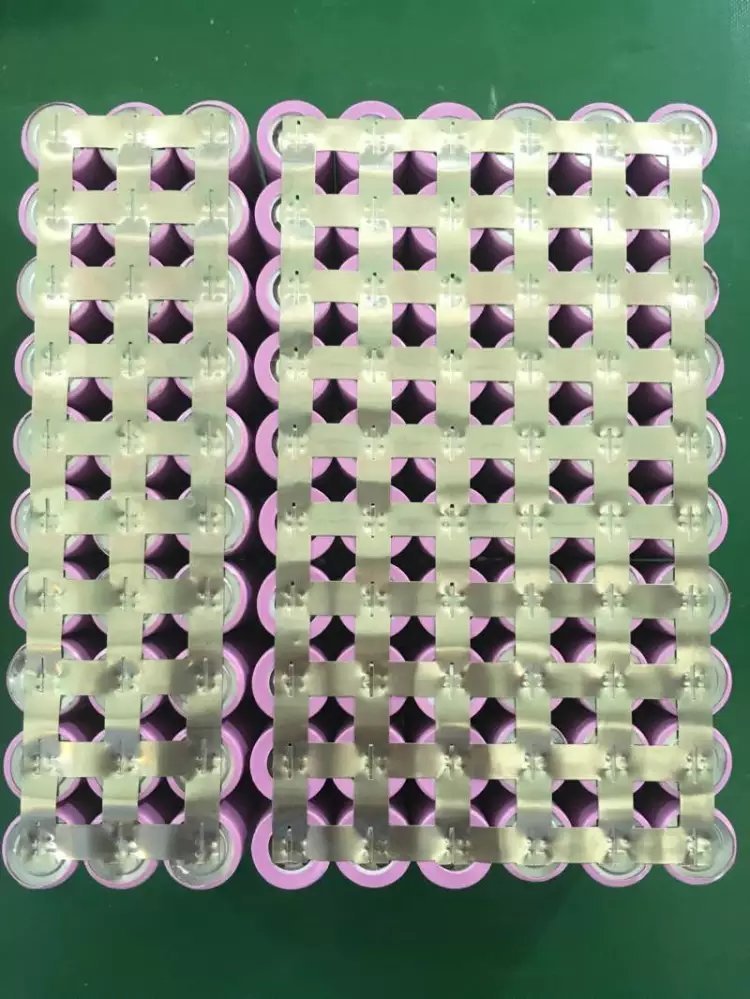

is suitable for electric vehicle battery packs, car battery modules, balance car battery packs, scooter battery packs, mobile power sources, start battery pack modules, power tool battery packs, notebook battery packs, etc. , various battery combinations!

Features

1 , Support breakpoint start, support automatic start and manual start mode conversion.

2 , programming is simple, supports any point programming and array programming , can realize jump spot welding, single point, double point mode fast switching, spot welding path optimization, improve efficiency, local disk can store programming file 99 group , USB interface can be graphic import .

3 , spot welding head takes the center point of two welding needles as the center of the circle, and the angle is continuously adjustable, which is suitable for spot welding of various special-shaped split connecting pieces.

4. The system is divided into operator, administrator, super user and other access screens to facilitate the use, management and maintenance of butt welding machines.

5 , adopts inverter DC welding power supply, stable performance, fast welding speed, constant current working mode, eliminating unstable factors of welding current for a long time.

6 , comes with welding current monitoring system, which can monitor welding current in real time.

7 , spot welding power supply has virtual welding alarm function , can directly communicate motion controller can record virtual welding position, welding needle replacement forecast reminder . The welding efficiency of

8 and is about 70 times that of manual 8 #, with high stability, labor saving and time cost saving .

TechnologyParameters

| Input Voltage |

Single Phase 200-240VAC 10% 50/60HZ |

| Z1 Axis Travel |

0-3 5 0 mm (customizable) |

| Z2 axis travel |

0- 3 5 0mm (customizable) |

| y axis travel |

0- 420mm (customizable) |

| W axis angle |

0 -180 degree |

| welding speed |

0.5 seconds/point; 3000 - 3600 PCS/hour |

| motor drive maximum speed |

1 5 00mm/ s |

| maximum load cell ( 18650) |

300pcs |

| Number of Storable File Groups |

99 Group |

| Operating System |

Motion Controller + Man-Machine Screen |

| Transmission Mode |

Spindle Closed Loop motor + screw + linear guide rail |

| spot welding head |

Dongling servo motor |

| angle adjustment |

stepping motor |

| welding nickel strip thickness |

0.1 mm-0. 3 mm; Split Bump over 0.2mm |

| Exterior Dimension ( mm ) |

1080 L * 900W * 1 60 0H |

| Repeated Positioning Accuracy |

±0.02mm |

and power supply parameters

1. equipment power supply:single phase 200-240 V AC 50 /60 H Z

or3Phase AC380V 10% 50/60Hz

2.equipment weight: about 200 KG;

3. Exterior dimensions: 1080mm (length) * 900mm (width) * 1600mm (height);

4. Operating environment:4

.1 Please avoid using this equipment in places with high temperature, high humidity, vibration or impact, metal powder and welding spatter, and pay attention to the control of ambient temperature around the equipment;

4.2 equipment must be grounded and separated from personnel grounding.5.

equipment service life : more than 5 years.

6. Welding power supply technologyparameters:

| Model |

IST-5000 |

||

| Input Power (V) |

3Phase AC380V 10% 50/60Hz / Single Phase200-240VAC 10% 50/60Hz |

||

| output current (A) |

5000A |

no-load voltage (V) |

10.8 |

| control mode |

constant current control |

Cooling Method |

Force Air Cooling |

| Welding Conditions |

8 |

Weight (Kg) |

30.3 |

| Overall Dimension (W×H×D) |

270 × 330 × 465 |

||

| transformer size (W×H×D) |

180 × 270 × 330 |

||

| 0.15-0.25 mm Nickel Sheet Welding |

|||

Previous Page

Previous Page

Next Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!