Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

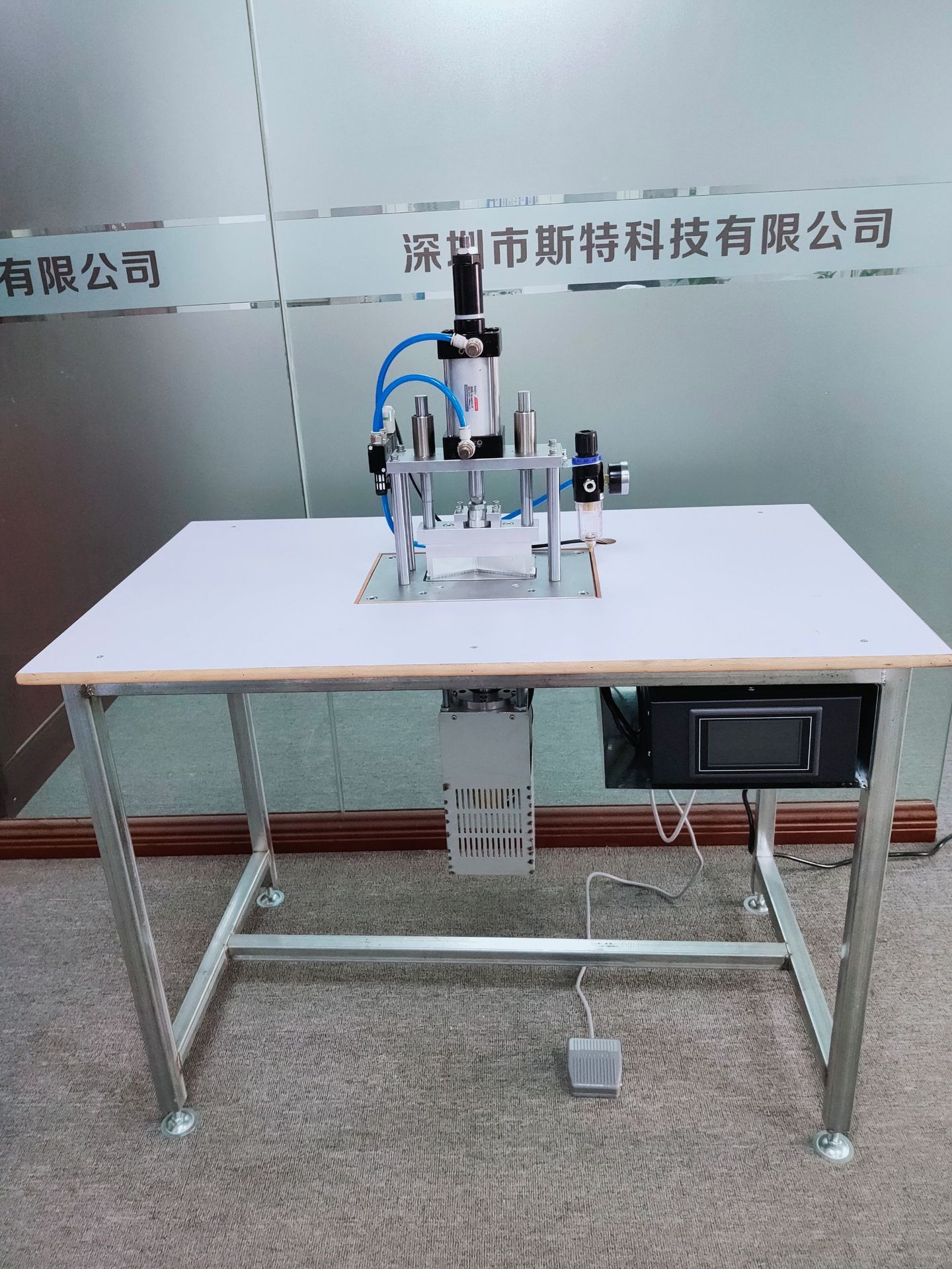

N95 mask spot welding machine

Classification:

Mask spot welding machine

Key words:

N95 mask spot welding machine

immediate consultation

Product Description

ultrasonic spot welding machine adopts microcomputer control, electronic tuning, frequency LCD display, continuous adjustable power, simple operation, stable and reliable work; firm welding, good consistency, welding parts have a firm welding surface, high strength, beautiful, Environmental protection and other characteristics. Ultrasonic metal spot welding machine is not only easy to operate, built-in electronic protection circuit, but also safe to use, for the same kind of metal welding, can implement single point or multi-point welding of non-ferrous metals; ultrasonic metal spot welding machine has been widely used in batteries and hardware products industry.

This machine is introduced: Spot welding machine has a wide range of uses. The biggest feature of this machine is dexterity, convenient operation and high efficiency! Multi-channel ultrasonic protection system, trouble-free repeated testing, high stability.

1. Eliminate the pinhole phenomenon caused by the traditional sewing machine. The processed products have the characteristics of good water tightness, high production efficiency, no needlework accessories, smooth melting surface without burrs, and good hand feeling..

2. Vibration can reach 20,000 times per second, can be processed when starting up, without preheating, easy operation, continuous processing, fast speed, high efficiency, low labor cost, simple mechanical operation, easy maintenance, 20KHZ low noise ultrasound, anti-noise

3. Ultrasonic spot welding machine is mainly used for sewing, welding, cutting, embossing, flower wheel replacement, all kinds of round flowers can be replaced according to the needs of customers. No preheating is required during production. Wrapping paper and gold foil can be packed at the same time, and preheating is not required during pressurization. Tang Jin function; Multiple special machines can be used to complete products with larger width at one time. The welding head is wear-resistant and has a long service life. Widely used in clothing lace, bed covers, pillowcases, car covers, tents, packing belts, backpacks, travel belts, portable belts, curtains, raincoats, windbreakers, snowcoats, toys, gloves, table towels, chair covers, quilt covers, masks, protective clothing, belts, hair accessories, accessories, umbrellas, and other industries. Applicable materials for

ultrasonic spot welder:

chemical synthetic fiber cloth, or chemical fiber blended and chemical film (containing more than 30% chemical fiber), can be processed into required products, such as Nylon cloth, needle and thread repair, non-woven fabric (spunlace cloth, ES material, PP non-woven fabric, etc.) T/R cloth, tedolong repair (Polyester cloth), multi-layer cloth, and all kinds of laminated coated cloth film paper can be applied.

KN95 Mask Edge Banding Machine Mask Ultrasonic Edge Banding Machine Mask Welding Surface Machine Factory Outlet

This equipment is greatly affected by fluctuations in ultrasonic prices and other parts. The exact price is subject to telephone inquiries with business personnel!!!

metal and other ultrasonic equipment

metal and other ultrasonic equipment

1. ultrasonic metal welding machine application principle

ultrasonic metal welding machine application has 20KHZ -40KHZ, its principle is to use the energy of ultrasonic high frequency mechanical vibration to weld the same or different non-ferrous metal materials, in the welding process, neither to the workpiece transfer current, nor to the workpiece transfer high temperature energy, only in the workpiece with 20KHZ -- 40KHZ high frequency in the surface of the cycle of vibration, and the corresponding pressure on the workpiece to form a solid state between the workpiece to achieve the welding effect. Ultrasonic metal welding used in lithium batteries is to weld conductive materials with different poles. The welding requirements are relatively high. The use of ultrasonic technology for welding is a better welding equipment for battery manufacturers. The main materials are (nickel sheet and copper sheet, aluminum Strip and aluminum foil, aluminum-nickel composite tape and aluminum shell, etc.).

Advantages of 2. Ultrasonic Metal Welding Machine

1) The welding material does not melt and is not fragile.

2) After welding, the conductivity is good, and the resistivity is extremely low or nearly zero.

3), low requirements for welding metal surface, oxidation or electroplating can be welded.

4), welding time is short, without any flux, gas, solder.

5), welding without sparks, environmental protection and safety

3. ultrasonic metal welding machine performance and technical parameters

1. Metal welding machine specifications, technical parameters:

| Operating frequency | 25KHZ |

| Rated power | 1000W-2000W |

| Input voltage | AC220V,50/60HZ |

| working air pressure | 0.2-0.8MPA |

| working mode | pneumatic, relay program control |

2. performance characteristics: (high welding efficiency, good welding quality and good after-sales service)

(1) adopts American ultrasonic technology, semi-automatic frequency tracking;

(2) adopts time relay to complete time and welding procedure;

(3) The main accessories adopt original imported accessories, with high energy conversion and utilization efficiency;

(4) The circuit is equipped with frequency offset and excessive current protection devices to ensure the stability of the equipment;

(5) Choose a low-cost replaceable welding nozzle, which is extremely hard, greatly reduce the wear of the welding nozzle, the integrated high hardness welding head,

welding head has multiple welding surfaces that can be installed quickly, so that the cost is low;

(6) The welding die can be quickly and conveniently replaced according to different application sizes. The installation of welding nozzles can effectively reduce the cost:

(7) The installation, debugging and operation of the equipment are simplified.

4. Ultrasonic Metal Welding Machine Application Range

1), Ni-MH Battery Ni-MH Battery Nickel Mesh and Nickel Sheet Mutual Melting and Nickel Sheet Mutual Melting..

2), Lithium Battery, Polymer Battery Copper Foil and Nickel Sheet Mutual Melting, Aluminum Foil and Aluminum Sheet Mutual Melting..

3) Wire Mutual Melting, Partial Forming One and Multiple Mutual Melting.

4), wires and famous electronic components, contacts and connectors are mutually fused.

5), large heat dissipation seats for famous household appliances and automobile appliances, heat exchange fins and mutual melting of honeycomb hearts.

6), electromagnetic switches, fuse-free switches and other high-current contacts, mutual melting of dissimilar metal sheets.

7), metal pipe tail sealing, cutting can be water, air tight.

metal welding suitability:

| metal material | suitability |

| brass | OK |

| aluminum | OK |

| copper | OK |

| gold | OK |

| Silver | OK |

| Tin | OK |

| Nickel | OK |

Common Failure List

| Failure Phenomenon | Failure Cause | Resolution method |

| Power On No Instruction | Fuse Blown | 1: check whether the power tube is burned out, 2: replace the fuse |

| according to the test, the ammeter does not show | 1: the power tube is burned out, 2: the high voltage capacitor is burned out, 3: the relay control part is faulty, 4: the line on the back of the main circuit board is burned out | replace the related accessories |

| according to the test, the current is too large or screams. | 1: The transducer, horn and welding head are not locked. 2: If there is no welding head and the current is large, there is a problem with this transducer or horn. 3: The characteristics of the power tube are mutated or burned out. 4: The power amplification part is faulty. | replacement of related accessories |

| step on the foot switch, the welding head does not come down or the control time is not allowed | 1: there is a problem with the solenoid valve, 2: there is a problem with the time relay. | replace solenoid valve or time relay |

Previous Page

Previous Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!