Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

IST-8000 Gantry Inverter DC Spot Welding Machine

Classification:

Gantry type battery spot welding machine

Key words:

IST-8000 Gantry Inverter DC Spot Welding Machine

immediate consultation

Product Description

1. project name: gantry inverter DC spot welding machine

2. model: IST-8000 (attached figure)

IST-8000 series intermediate frequency resistance welding machine controller is one of the high-quality products of Shenzhen st technology co., ltd. it is controlled by microcomputer, so it can obtain accurate control quantity, with working parameter setting and memory function. Easy to set up, excellent performance, low failure rate, sturdy and durable.

3. IST inverter DC spot welding machine main features

IST-8000 series intermediate frequency welding machine controller is a spot welding machine synchronous controller with DSP chip as the main control unit. The main functions and features of this series of controllers are as follows:

l 32 sets of welding specification storage: more flexible selection and control can be made during welding.

l can set the preheating current, welding current and tempering current, which effectively solves the problems of splashing during welding and quenching of the workpiece after welding. The three discharge pulses may be used individually or in any combination.

l has a current slow rise/slow fall function: using the slow rise/slow fall function can avoid splashing during welding and meet the welding requirements of special materials.

l counting function: With counting function, you can count the number of welding. Using this function, you can easily understand the work efficiency.

l has single point/continuous/seam welding function

l energy saving: three-phase power input, intermediate frequency 1000Hz output after rectification and inversion, high working frequency, low transformer loss, and obvious energy saving effect.

l Easy to install and use: Compared with the transformer used in the intermediate frequency inverter welding machine, the volume is greatly reduced, the overall equipment is light and easy to install and use.

l Fault diagnosis and automatic protection function: During the working process, if the controller detects an abnormal situation, it will automatically shut down the output and give a friendly reminder.

l communication and BCD code control function: external industrial control computer, PLC and other equipment can be connected to realize remote control automation management and improve work efficiency.

l scalability: using German Bosch technology, it can be formed through the combination of various expansion modules of the company:

1: remote monitoring

2: real-time data feedback

3: programmable input and output

4: man-machine dialogue operation wireless connection

4. power supply basic parameters:

control system power energy |

|

control mode |

one pedal two valve |

function selection |

adjustment / welding |

specification storage quantity |

32 group |

room control system |

|

preloading time |

0-999 9 ms |

pressurization time |

0-999 9 ms |

slow rise time |

0-99 9 9 ms |

Welding 1 Time |

0-9 9 99 ms |

Cooling Time |

0-99 9 9 ms |

Welding 2 time |

0-9 9 99 ms |

cooling time |

0-99 9 9 ms |

welding 3 time |

0-99 9 9 ms |

descent time |

0-9 9 99 ms |

cooling time |

0-999 9 ms |

pressure holding time |

0-9 9 99 ms |

rest time |

0-9 9 99 ms |

heat control |

|

heat 1 |

0-999 |

heat 2 |

0-999 |

heat 3 |

0-999 |

welding current |

0- 400 |

welding voltage |

reservation |

assembly parameters |

|

working voltage |

3 phase 4 wire system AC380V +10% 50Hz |

output voltage |

single phase PWM output 500V |

output current |

rated continuous output maximum current 800A |

cooling mode |

forced air cooling +water cooling |

air valve power supply |

DC 24V ±10% current <150mA |

ambient temperature |

-10 ℃ ~55 ℃ |

Relative Humidity |

80% |

Shell Size |

360mm × 230mm × 600mm |

5. Table Parameters

1. Welding Input Power Supply: three-phase AC380V ± 10% 50/60Hz;

2. Maximum transformer voltage: 30V;

3. Maximum current output: 8000A;

4. Welding thickness of parallel nickel strip: 0.05~0.2mm;

5. Welding thickness of bump nickel sheet: 0.2~0.5mm;

6. Height adjustment range of welding head: 50-150mm;

7. Range of battery pack moving platform:(X direction: 250mm Y direction: 500mm);

8. Equipment air pressure: 0.2~0.7Mpa;

9. Equipment weight: 50 KG;

10. Exterior dimensions: 920mm (length) * 600mm (width) * 1300mm (height).

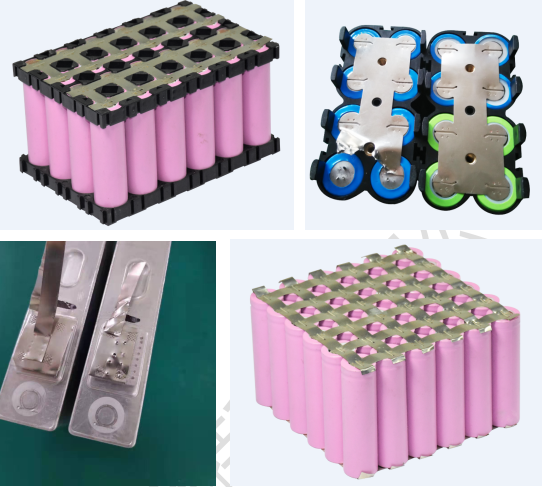

6. battery pack welding legend

Previous Page

Previous Page

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!