Language: Chinese

Service Hotline

Products

Contact Us

National 24-hour service hotline

Head Office: One Building, Baotian Baoshu Science and Technology Industrial Park, xixiang street, Bao 'an District, Shenzhen City

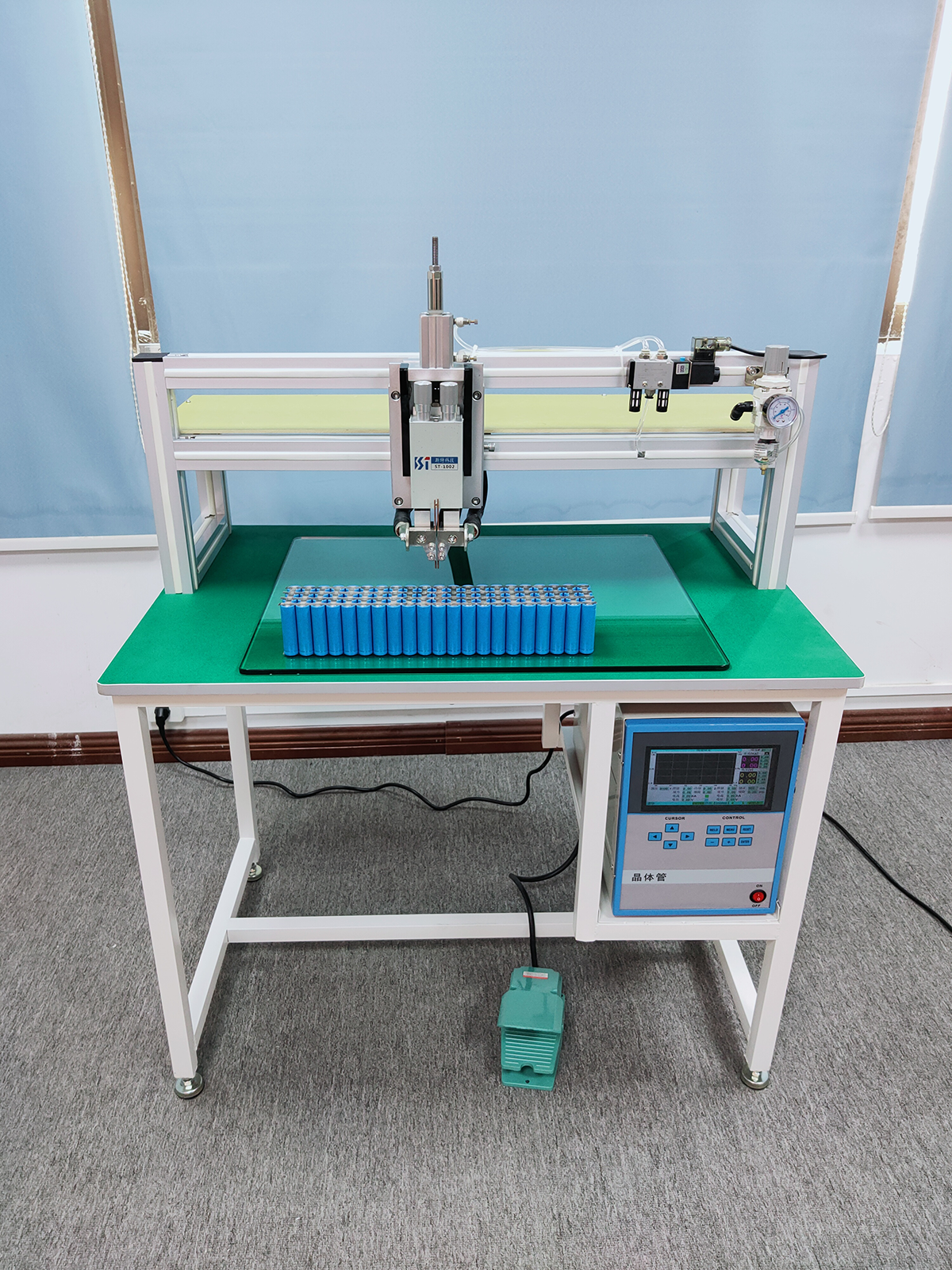

MDC-6000 gantry transistor spot welder

Classification:

Gantry type battery spot welding machine

Key words:

MDC-6000 gantry transistor spot welder

immediate consultation

Product Description

1. Project Name: Gantry Transistor Spot Welder

2. Model: MDC-6000 (Attached Figure)

3. Features

MDC Series uses capacitor energy storage transistors to control the power supply for discharge. Since the energy stored in the capacitor is used to connect and weld, small power supply equipment can also be used. Controlled by a 32-bit microprocessor, digital energy setting, precision control of welding energy, its alarm function can effectively detect the welding current, so that the welding results more solid and more beautiful, anti-interference design, reliable operation. The unique and excellent characteristics of double pulse welding can provide better welding quality pulse, using different energy to discharge the welding object twice in succession. The first pulse removes the dirt on the solder surface and makes the electrode better aligned with the base surface. The second pulse welds the base material, so the welding is firm, beautiful, less spatter and safe to operate. Using precise digital control, it can pre-store 32 sets of parameters, and can be changed and called at will; color screen LCD can easily display the welding parameters and curves. Discharge time can be accurately controlled, so that the solder joint is firmer and more beautiful; the minimum division of welding adjustment time is 10ms, so that the accuracy is more accurate.

4. working condition

power supply

input power supply is single-phase mains 200-240V/50HZ (or 60Hz) alternating current, input power

current is greater than 10A, ground wire and reliable grounding are required.

temperature

transistor welding machine is a high-precision welding equipment, and the transistor inside is more affected by temperature than

, so the equipment is suitable for working in an environment of 0-40°C, and the recommended working temperature is room temperature.

Electrical Parameters

Specification Specification

Specification |

MDC-6000A |

MDC-3000B |

MDC-2000A |

MDC-2000B |

MDC-5000B |

MDC10000A |

||||||||

Maximum current |

6000A |

3000A |

2000A |

2000A |

6000A |

10000A |

||||||||

Form |

Standard Type |

Polarity Switching Type |

Standard Type |

polarity switching type |

polarity switching type |

standard type |

||||||||

maximum power consumption |

300W |

350W |

||||||||||||

maximum welding current |

6000A |

3000A |

2000A |

2000A |

6000A |

10000A |

||||||||

Maximum Voltage |

30V |

|||||||||||||

control mode |

1. constant current control 2. constant voltage control 3. current and voltage combination mode |

|||||||||||||

preloading time 0000-2999ms |

||||||||||||||

time setting |

rise time 0.00-9.99ms |

|||||||

welding 1 , welding 2 time 0.00-9.99ms |

||||||||

cooling time 0.00-9.99ms |

||||||||

descent time 0.00-9.99ms |

||||||||

holding time 0000-999ms |

||||||||

Current Setting Range |

0.00-6.00KA |

0.00-3.00KA |

0.00-2.00KA |

0.00-2.00KA |

0.00-6.00KA |

0.00-9.99KA |

||

voltage setting range |

0.00-9.99V |

|||||||

specification current up and down limit setting |

0.00-9.99KA |

|||||||

Specification Voltage Up and Down Limit Setting |

0.00-9. 99V |

|||||||

monitoring display |

power-on 1*2 (current effective value / voltage effective value), power-on 1 2 (current peak value / voltage peak value) |

|||||||

input power |

Single Phase 100-120VAC/ Single Phase 200-240VAC 50/60Hz |

|||||||

Overall Dimension (mm) |

203 (Width) *310 (Height) *368 (Length) |

203 ( width ) *310 ( height ) *446 ( length) |

||||||

5. gantry transistor spot welder performance characteristics

1. high current transistor spot welding power supply is adopted, stable welding performance.

2. Adopt split design, the height of the welding head is adjustable, and the position is adjustable.

3. Gantry structure, suitable for electric vehicle battery pack, car battery module, balancing car power

pool group, scooter battery pack, mobile power supply, starting battery pack module, electric tool battery pack,

notebook battery pack and other

6. equipment and workbench parameters

1. Welding input power supply: single phase 200-240VAC

50/60Hz;

2. Maximum voltage of transformer: 30V;

3. Maximum current output: 6000A;

4. Welding thickness of parallel nickel strip: 0.05~0.2mm;

5. Welding thickness of bump nickel sheet: 0.2~0.5mm;

6. Height adjustment range of welding head: 50-150mm;

7. Battery pack moving platform range:(

X direction: 250mm Y direction: 500mm);

8. Equipment air pressure: 0.2~0.8Mpa;

9. Equipment weight: 50 KG;

10. Exterior dimensions: 920mm (length) * 600mm (width) * 1300mm (height).

7. battery pack welding legend

Top Recommended Products

Quality is the soul of the product, strictly abide by every standard of product selection, every process of production

Company News

Industry Information

2023-06-14

immediate consultation

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!